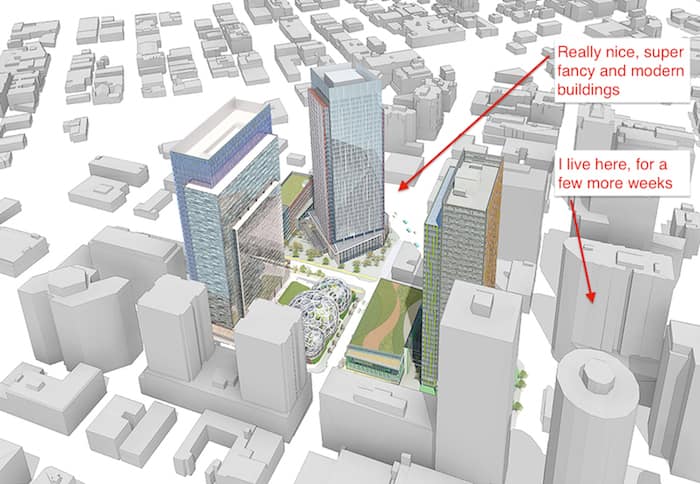

The above image is a view from my apartment on February 14th, 2014. Do you know what is being built? This hole is the first of three towers that Amazon is building on the edge of downtown Seattle. In the end these towers will house something like 15,000 employees and completely transform-for better or worse-this corner of Seattle.

The above image is a view from my apartment on February 14th, 2014. Do you know what is being built? This hole is the first of three towers that Amazon is building on the edge of downtown Seattle. In the end these towers will house something like 15,000 employees and completely transform-for better or worse-this corner of Seattle.

If you read through all the available literature on this project (there is a ton online), the design is fairly advanced. The glass domes that will make up the onsite retail space were probably generated using some fancy software and it’s a safe guess that the phrase “perimetric design” was tossed around a lot in various design meetings (wild speculation, but is there any doubt?). I don’t know any of the details of the actual design process, but I can image like any modern skyscraper some BIM platform was used and there were enough computer generated renderings created to reach from Seattle to Portland (again a guess, but what modern firm isn’t producing tons of glossy renderings for fancy projects these days). I can also imagine that physical models were built too, maybe even using 3D printing. One can hope. All of this is cutting edge architecture office stuff, and let’s be honest: a bit run of the mill for most big firms. Not a slight here, just big architecture firms have the resources and drive to tackle all that stuff for large projects. In addition to the process of design being pretty forward thinking (I assume), so too are the buildings themselves. You can read details here. It’s all good and again not too surprising for a prominent architecture firm and client: shooting for LEED Gold, a mix of amenities for the public and the workers, some high design moments and some more reserved, but competent portions (buildings can’t be all flare…I’m looking at you EMP Museum).

Progressive Building, Client, and Firm, but a lot of classics too

It’s awesome getting to watch this building go up. Every day I stare at the hole in the ground that will be the first tower. My 24th floor apartment overlooks it. Which means my apartment has an awesome view of the construction, the Space Needle, and views north to Puget sound. But after the tower is done, my apartment (which I’ll have long since left) will have only the Amazon tower to look at-well in that direction. There are some cool stuff to look at directly to the west and southwest (sorry I digress). When I moved to Seattle, the construction site was just a hole with a dirt floor. Then it became a hole with a concrete floor. For the last few months workers have slowly been putting up the form work for subsequent parking garage floors and the main elevator shaft. Here is the first tower today, on June 17th, 2014. There has been quite a bit of progress in the past four months, sort of.  Day in and day out I watch the construction site. I’ve watched plenty of highrises go up-one of the perks of going to architecture school in Houston-and I’ve walked more wood framed construction sites than I can remember, but there is something unique about having a bird’s eye view of the construction over such a long period of time. Different aspects come into view. Primarily my months long vigil has highlighted how archaic the whole process is. All the materials are delivered essentially by hand; sure the crane lifts things, but one truckload at a time. And at the start and stop of every lift is some guy (almost always a dude) on street level or deep in the bowels of the hole watching and helping guide the rebar, form work, etc. to it’s final spot. And of course then all the individual pieces of rebar or cabling or form work are placed by hand. One by one by one. At a small scale this is not that surprising or interesting; I’ve seen this done tons of times. But I’ve never really thought about it on the scale of a highrise. Or THREE highrises all in sequence. They will build and unbuild the main structure of these buildings out of wood and steel form work in order to actually build them out of concrete. They will build the main structure of these three highrises twice, by hand, each time out of different materials. Our gleaming future is built pretty crudely.

Day in and day out I watch the construction site. I’ve watched plenty of highrises go up-one of the perks of going to architecture school in Houston-and I’ve walked more wood framed construction sites than I can remember, but there is something unique about having a bird’s eye view of the construction over such a long period of time. Different aspects come into view. Primarily my months long vigil has highlighted how archaic the whole process is. All the materials are delivered essentially by hand; sure the crane lifts things, but one truckload at a time. And at the start and stop of every lift is some guy (almost always a dude) on street level or deep in the bowels of the hole watching and helping guide the rebar, form work, etc. to it’s final spot. And of course then all the individual pieces of rebar or cabling or form work are placed by hand. One by one by one. At a small scale this is not that surprising or interesting; I’ve seen this done tons of times. But I’ve never really thought about it on the scale of a highrise. Or THREE highrises all in sequence. They will build and unbuild the main structure of these buildings out of wood and steel form work in order to actually build them out of concrete. They will build the main structure of these three highrises twice, by hand, each time out of different materials. Our gleaming future is built pretty crudely. Think about it. Amazon is one of those companies that is fundamentally changing the way we live. They are legitimately researching and developing how to incorporate drones into their delivery scheme. Amazon, whether you love them or hate them, is pushing to change the world. Can you even remember when you couldn’t order ANYTHING you wanted online and get it as soon as you wanted it? It wasn’t that long ago. Here’s that company, hiring really smart, forward thinking architects, engineers, and contractors to design and build three really big and fancy buildings. And they are doing it by hand, just like we were doing it one hundred years ago, more or less. This construction site would make way too much sense to the builders of the Empire State Building or the Monadnock Building in Chicago. Sure one of those buildings was steel and the other iron and load-bearing masonry, but how much has changed? How different would those job sites look to a (semi) educated neighbor 300-odd feet up? Sure the cranes are bigger, there are GPS and laser positioning, cellphones are everywhere, and maybe there are even a few tablets, but how far back in time would we have to go to find a construction worker who wouldn’t be easily integrated into the team (once he got over the wonders of being a time traveling construction worker)?

Think about it. Amazon is one of those companies that is fundamentally changing the way we live. They are legitimately researching and developing how to incorporate drones into their delivery scheme. Amazon, whether you love them or hate them, is pushing to change the world. Can you even remember when you couldn’t order ANYTHING you wanted online and get it as soon as you wanted it? It wasn’t that long ago. Here’s that company, hiring really smart, forward thinking architects, engineers, and contractors to design and build three really big and fancy buildings. And they are doing it by hand, just like we were doing it one hundred years ago, more or less. This construction site would make way too much sense to the builders of the Empire State Building or the Monadnock Building in Chicago. Sure one of those buildings was steel and the other iron and load-bearing masonry, but how much has changed? How different would those job sites look to a (semi) educated neighbor 300-odd feet up? Sure the cranes are bigger, there are GPS and laser positioning, cellphones are everywhere, and maybe there are even a few tablets, but how far back in time would we have to go to find a construction worker who wouldn’t be easily integrated into the team (once he got over the wonders of being a time traveling construction worker)?

I don’t have much else to add. I don’t have the solutions, but we need to do better. How much longer til we have a bit more automation on the construction site? Where are the constructo-bots? And what are we all doing to bring that future a bit closer to reality? These are some of the reasons why I’m so fascinated with BIM and some of those other topics I focus on. It’s my way of working towards a more integrated and exciting future for the construction industry.

Subscribe to my blog to read more about the tricky world of being an Architect in the 21st century: Shoegnome on Facebook, Twitter, and the RSS feed. If my career as an architect lasts as long as it should, I am going to be really grumpy if I never have a building built by robots.

5 thoughts on “In Need of an Update”

It is interesting topic, what about the prefab modular building site? I’m sure the transported time traveling construction worker would be a little stumped working out how and why you would build part of a buildingin aa factory.

Absolutely! I think prefab offers some exciting possibilities. Someone else shared this video with me after reading the post: https://www.youtube.com/watch?v=r3l2LRiwkDM

And much like prefab-whether walls, whole stacked units, plug & play spaces like factory built bathroom units, etc. my article glosses over that eventually a lot of pre-built stuff will arrive on the construction site. Windows, prehung doors, etc. When I think of these things, it’s still just bigger versions of the same concept: we no long site finish stone or forge nails locally. We do that elsewhere and transport to the site for final installation. First came nails, stone, and precut lumber. Then windows, doors, and slightly larger construction elements (precast concrete for example). That’s all real broad strokes of course. Much of prefab is just an extension of that. Instead of delivering some studs we deliver a wall. But that wall is still eventually finished by hand. It’s all moving in the right direction. And like the video above and some other examples out there, the cutting edge of prefab materials is REALLY exciting and arguably different from the past.

I’m curious to see how it all comes together. Prefab/factory built/and 3D printing. It seems like there’s some amazing automated convergence waiting to happen there. And the few opportunities I’ve had to work with prefab/kit built/etc. has been really fascinating. Makes me want more!

Oh related to all this. On my daily drive to daycare I first pass these buildings then a little later I drive past a 5 or 6 story building that is panelized. All the exterior walls are being delivered by truck and installed quite quickly. The floors are still traditional site built, as are all the insides. But it’s a move in the right direction, I think.

Very interesting subject. We (construction and architecture trade) are considered the last of the very big industries to still be working in the stone age. Tedd Benson (guru of residential and timber framing) wrote a piece on this pertaining to the residential homebuilding process. His company is pioneering ways to change this process. I always have the same thought when I am on a construction site, regarding the hand built process and also how dangerous the overall process can be.

Here is a link to his article:

http://thebuildingcycle.com/2014/04/07/seriously-tedd-benson-on-homebuilding/

Awesome article. And wow those images. Just wow. The work I’ve gotten to do with people trying to build different has been very inspiring. And has helped me adapt how I work in BIM to design better. A slow, slow virtuous cycle.

A complex project I worked on in 2005-2009 (Hamilton Island Yacht Club) was challenging for a number of factors:

1. Remote site – an island on the Great Barrier Reef, about 10km from the coast. Building material access was by barge, with limited hours. Site prone to cyclones, tidal surge, soil liquidation, methane clathrates(!!! Google it – scary things) and strict tourist season rules (no wolf-whistles).

2. Challenging design – almost no straight lines anywhere in the building. Massive concrete cantilevers. Double-curved sectional spiral copper roof.

At the time we started the project, BIM wasn’t even an acronym yet, but we were ‘doing BIM’ from first principles – sharing 3D design data, relying on embedded metadata instead of traditional details.

We also used a couple of experimental construction techniques – our concrete formwork (double curves everywhere) was proving so expensive in ‘traditional’ methods, we worked out it would be cheaper to make the formwork in modular steel sections – effectively ‘Lego’ formwork. Result – cheaper, quicker, easier, and a better finish on the concrete.

The second ‘alternative’ we used was for the massive amount of custom (curved, of course) timberwork required – we got sick of the outrageous bids by ‘traditional’ builders, we went to boatbuilders instead. They had their own 6-axis milling machines, and were experienced in ‘flatpack’ luxury super-yacht fitouts. We gave them our full Revit file, they machined all the timber in a weekend. The timberwork went together like Lego on site.

Similar ‘alternative’ construction methods were used for the structural steel and copper roofing.

By the way – notice my reference to Lego? Have a look at a current set of Lego instructions. Detailed, step by step isometric specifications, with a detailed pictorial BOM at the back. No words, just step numbers. Once my drawings look like that, I will be HAPPY!